Modular Extraction Booths

Cannalab modular panel extraction booths are built to NFPA guidelines and peer-reviewed to provide your team with a safe and compliant environment for processing. Class 1 Division 1 rated for hazardous solvent use, each booth comes standard with interlocking controls, audible/visual alarm system, spark proof fans and gas detection monitor.

Speed to market is key in this industry. Cannalab Innovations is streamlining that process to get your business operational and making money. Building your own C1D1 room usually results in extended delays and higher expenses. Tracking down a qualified engineer, design R&D, approval, hiring contractors and inspections could take months. Pre-designed booths are ready for market in 6-8 weeks! Completely produced in-house for faster lead times and the best competitive pricing in the market. UL Certification coming soon!

Have questions about what classification room you require? Read here. What's the difference between C1D1 and C1D2?

Speed to market is key in this industry. Cannalab Innovations is streamlining that process to get your business operational and making money. Building your own C1D1 room usually results in extended delays and higher expenses. Tracking down a qualified engineer, design R&D, approval, hiring contractors and inspections could take months. Pre-designed booths are ready for market in 6-8 weeks! Completely produced in-house for faster lead times and the best competitive pricing in the market. UL Certification coming soon!

Have questions about what classification room you require? Read here. What's the difference between C1D1 and C1D2?

Models

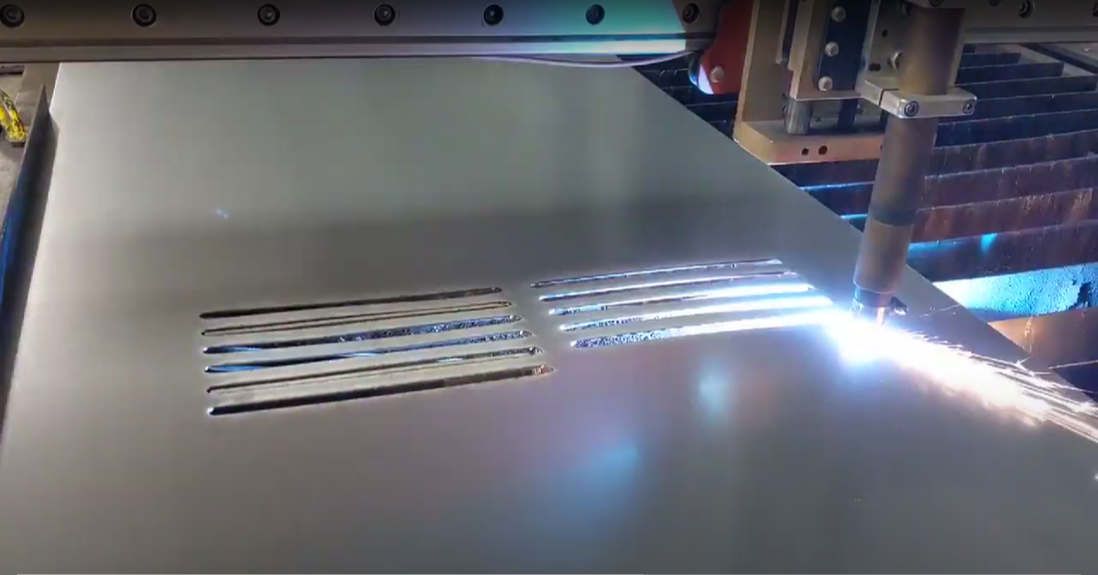

Structure is 100% made in-house from 18-gauge steel with a unique overlapping flange design that provides a superior seal and structural strength. You can have the option of a sky white powder coat, or a hot dipped galvanized and save money!

Equipment included is UL listed and rated for either Class 1 Div.1 or Class 1 Div. 2 use in hazardous areas. The gas meter is easy to see with green, yellow, and red back lighting that signify current alarm status, and has a very user-friendly UI that can allow flexibility for a customized fit to your exact process solvents. (Butane, Ethanol, Heptane, Hexane, Propane, Pentane, etc.)

CO2 systems are to be designated for that process ONLY. Meter sensors cannot be calibrated to a different gas type due to mounting location required. Fans are USA made, Class 1 Division 1 rated, high flow construction and UL Listed. Compliant with NFPA, UL, NEC, ASME, IFC, IMC standards and peer-reviewed by third party engineers to ensure those standards are met.

Controls are built with the highest-grade UL Listed automation components. We spared no expense here! Decked in Allen Bradley, Eaton, and Schnieder components. We designed this panel to keep operations reliable. We have focused on eliminating the possibility of human error just like you will see in hospital automation systems. Interlocking fans with the gas meter to ensure they are operating at all times. Low maintenance design that can be serviced quickly with readily available components that are always in stock at our supplier. We ditched the fancy logic controllers and built a rock-solid automated panel to keep you operating instead of waiting for unique parts and software programming from limited resources.

Alarms are multi-staged at different Lower Explosive Limits (LELs) to purge the booth of excess hazardous gas fumes and to notify the operator that LELs have reached dangerous levels that require further actions. Each booth comes standard with C1D1 rated interior strobe light and a 103dB audible horn on the exterior that emit when alarm Stage 2 has been triggered or when there is a fault in the gas meter operation.

|